Iron Phosphate Coatings

Iron phosphate coating is one of the most preferred phosphating methods, especially spraying lines. It is a type of coating made on materials to be used in the interior environment after painting. It is applied before painting and increases the ability of the paint to adhere to the metal surface. Although it provides lower corrosion resistance compared to zinc phosphate coating, it is preferred to be easy to use, to form less sludge, to work at lower concentrations and temperatures.

It can be used for iron, steel and galvanized surfaces by dipping and spray application mostly.

Iron phosphate products can be used with neutral degreasing products in spray iron phosphating lines. In this way, both the degreasing and phosphating of metal parts are done at the same time.

Zirconium coatings are new generation systems alternative to iron phosphate coating. It provides higher corrosion resistance and less sludge formation. It can work at ambient temperature. When used with neutral degreasing products, elevated temperature is needed for the degreasing effect. Compared to iron phosphate baths, water quality (hardness, conductivity, etc.) should be higher.

Iron Phosphate Coating Chemicals and Products

Concentrated coating products are usually in liquid form, clear, colorless or light yellow in appearance. Surface active products used as additives for degreasing are generally in liquid form and have high viscosity. All products are packaged and sold in plastic drums or IBC tanks that are resistant to chemicals and comply with international dangerous goods transport rules.

It is applied especially for iron and steel before electrostatic powder coating. Easy-to-use product used in spraying systems, used as single product for degreasing and phosphating with stable bath values. At the last stage, high corrosion resistance and paint adhesion are provided with passivation application.

It is used to increase the adhesion and corrosion resistance of the paint to the surface for iron, steel, aluminum and galvanized materials. It is applied by dipping or spraying method. When used as a single bath, it can work at ambient temperature. It provides high paint bonding ability and less sludge formation.

Used in iron phosphate coating baths for iron and steel materials. It is applied by spraying or dipping method. By adding a neutral degreasing additive, degreasing and phosphating can be achieved in a single bath. Efficient operation is provided by increasing the usage rate of degreaser additive for cleaning heavily greased parts.

It is used in spray iron phosphating lines for iron, steel, aluminum and galvanized materials. While it provides high corrosion resistance for iron and steel parts, it creates more surface abrasion compared to standard iron phosphate products, providing better adhesion of paint, especially on aluminum and galvanized surfaces.

Suitable for iron, steel and galvanized steel. Before iron phosphating, degreasing must be applied. If there is rust on the metal, it must be passed through the rust removal baths. Starting from blue, it forms a phosphate layer in light yellow, red and gray appearance. Coating weight is in the range of 0.2-0.8 g/m2.

It is a one-component, low use concentration, powder form, stable and easy-to-use product which is applied by dipping or spraying method for iron and steel materials. It contains degreasing additives. At the last stage, high corrosion resistance and paint adhesion are provided with passivation application.

It is suitable product to be used in pressure spray machines for iron, steel and galvanized steel. Thanks to the surface active materials it contains, degreasing and iron phosphating takes place at the same time. After the iron phosphating process is finished, the parts need to be dried quickly.

Used by hand wiping or brushing for iron, steel and galvanized materials. It simultaneously degreases metal parts and forms iron phosphate coating. Easy-to-use product that can be applied at ambient temperature. A 10% bath solution is sufficient for application. Parts must be dried quickly after cleaning.

Iron phosphating chemical used for iron and steel materials by hand wiping and brushing. It is a practical and economical product that provides cleaning of metal parts and iron phosphate coating at the same time. It is used by mixing with water at a rate of 5-10%. Metal parts must be dried quickly after cleaning.

It is a suitable product for aluminum and galvanized materials together with iron and steel, applied by hand wiping and brushing method at ambient temperature. It provides superficial etching, which will increase the paint adhesion ability on aluminum and galvanized steel. It is applied with a 10% use concentration.

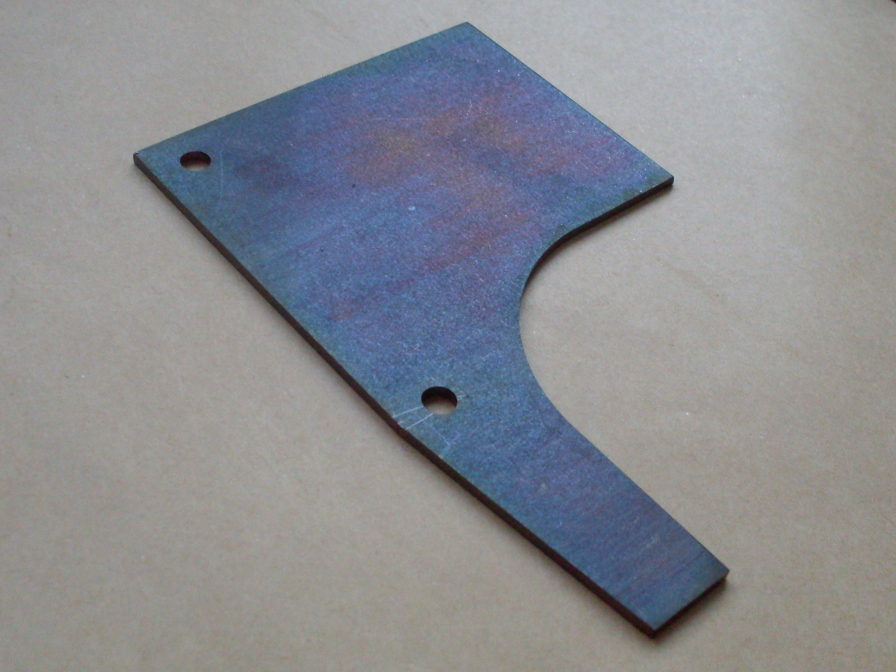

Iron Phosphate Conversion Coating Images

Depending on the properties of the phosphating chemical and the application time; light yellow, light blue, dark blue or iridescent color may occur on the dried steel surfaces. After washing, phosphating and drying, oiliness, dusting and rusting should not be seen on the surface.

Iron Phosphate Coating - Dip Application

Notes:

* Image of iron phosphate coating before electrostatic powder coating for laser cut steel part.

* Coating process was done with product PHORYL 1080.

Iron Phosphate Coating - Spray Application

Notes:

* Photo of iron phosphate coating used in towel warmer production.

* Coating process was done with product PHORYL S 980.